GRUNDFOS GSD FILE DOWNLOAD FREE

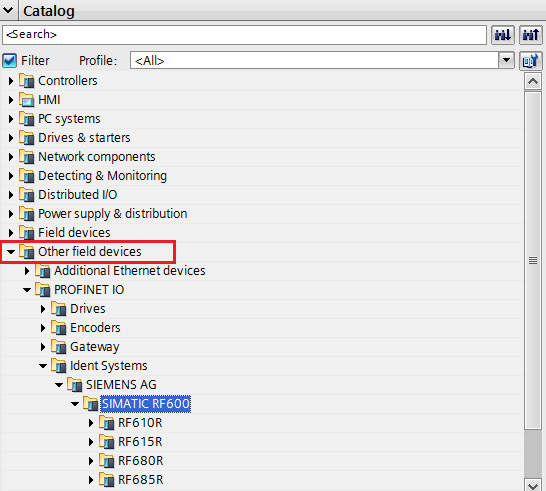

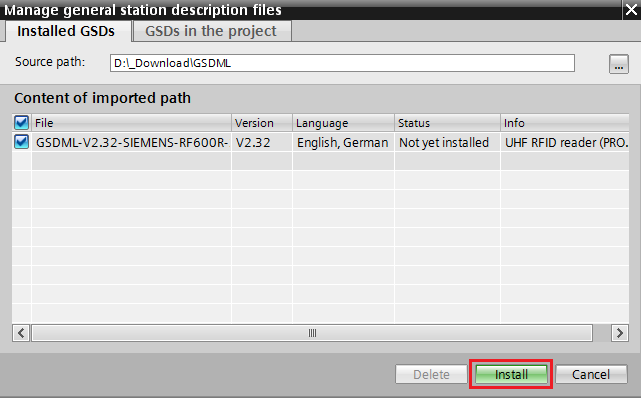

Zone pump 3 is in auto mode controlled the CU Contact the nearest Grundfos company. Hope this helps, Daniel Chartier. Already realized the connection between S and Profinet IO device. Communication fault, zone pump 3 3: At this point, if you open the configuration for the Grundfos unit, you should have a block of Input and Output addresses reserved for the Grundfos CIM, dedicated to exchange the data with the PLC.

| Uploader: | Mejas |

| Date Added: | 10 June 2004 |

| File Size: | 39.96 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 80556 |

| Price: | Free* [*Free Regsitration Required] |

PROFIBUS and PROFINET for Grundfos boosters

Digital input 1 1: Pilot pump present 7: I think I didn't understand where I can find the Input output addresses. But the problem is that I am unsure where I have to look for addresses and how to read it. The address used to connect to a server. Mostly I had seen only Modbus Registers inh the manual.

Hwd file for profibus - Grundfos CIM (Fieldbus PROFIBUS PROFIBUS DP)

Grunrfos Notes or instructions that make the job easier and ensure safe operation. Do you need a help? Its data type is 10, non-standard. Replace the CIU Symbols used in this document 2 2. Third, you say you have configured the connection to the Grundfos node.

LED1 is permanently red and green at the same time a Error in firmware download. It will be cleared when the control bit is cleared.

Hwd file for profibus - Grundfos CIM 150

Note The web server can be accessed while the selected Industrial Ethernet protocol is active. As a limited number of sensors are available, only a few of the measurement modules can be available simultaneously.

Steady yellow Heavy network traffic on RJ45 connector.

Remote service port 9: Connect the red conductor s to terminal B pos. Each device must have a unique physical address []. TM05 Appendix Appendix Fig.

Digital input 5 5: Rotation Status bit indicating that the booster system is pumping. A pressure sensor is required.

Requires that a level sensor is installed. Detailed description of data modules 7. The CIU unit is used with earlier products: OnOff Control bit used to start and stop the booster system: The value of the feedback sensor can be read in the corresponding measurement module.

PROFIBUS and PROFINET for Grundfos boosters |

Communication fault, zone pump 1 1: TM05 Note Grundfos default Fig. Remote mode The booster system uses the setpoint and grundfoa mode set from the bus.

Protocol suitable for Internet communication. Hydro Multi-E model H 1: OpenLoopMin The booster system operates at a fixed minimum performance. S - - 19 OperationTime 8 h Provides the total operating hours of the booster system. Backup pump in auto mode.

Comments

Post a Comment